Flexible Metal Conduit

Anamet Electrical, Inc. is a leading manufacturer and supplier of flexible metal conduit systems. We distribute our flexible metal conduit around the world. Our partners in Canada and Europe work with us to manufacture and deliver UL-approved liquid tight flexible metal conduit systems. Furthermore, application of in-house capabilities and years of expertise meet and exceed needs for electrical safety solutions.

Our flexible metal conduit adheres to the safety standards of the National Fire Prevention Association (NFPA), National Electrical Code (NEC), Underwriters’ Laboratories (UL) and Canadian Standards Association (CSA). We also offer flexible conduit fittings in different materials to safely connect conduits.

Types of Flexible Metal Conduit

Since 1908, our company has designed and manufactured flexible metal conduit to protect wiring where it was installed.

We offer three flexible metal conduit types::

-

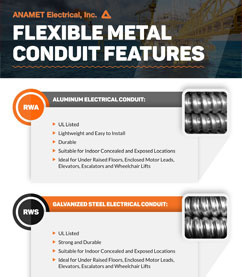

Flexible Metallic Conduit (FMC): The most common style of metal conduit (also called Flex or Greenfield) is made of aluminum or galvanized steel strip. This strip is coiled tightly so the leading and trailing edges of the strip engage and interlock. Even though it is not watertight, this conduit protects wiring from dust and metal particles. The spring-like appearance of the wound metal strip makes the conduit flexible and crush resistant.

-

Extra Flexible Metal Conduit: We offer Type DE-710 and Type DSL extra flexible metal conduit to meet industrial needs. These conduit types are roll formed for superior flexibility and durability in yellow brass, stainless steel or other metals. An ovalized variant is available for protecting wiring in confined spaces such as medical and office furniture. Since 1956, our industrial partners installed this conduit to protect their electrical and mechanical control equipment.

-

Liquid Tight Flexible Metal Conduit (LFMC): This flexible metallic liquid tight conduit has different coil shapes, with or without fiber or wire packing. A liquid tight polymer jacket is extruded over this conduit to protect wiring from corrosion and moisture. LFMC is similar to FMC, but it is encased in plastic, for a liquid tight seal when installed with correct fittings. The conduit coat, durability and corrosion resistance make this conduit an ideal choice for outdoor use or ground burial.

Our Line of Flexible Metal Conduit Products

We have different flexible metal conduit products you can choose from. Our complete line consists of the following:

-

Type RWA - Reduced Wall Aluminum Flexible Metal Conduit (FMC)

-

Type DE-710 - Heavy-Duty, Extra Flexible UL Recognized Component for OEMs

-

Type ASUA - Anti-Static, UL Listed, CSA Approved, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type UA - UL Listed, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type HTUA - Higher and Lower Temperatures, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type CW - Computer Blue, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type ZHUA - Zero Halogen-Low Smoke-Low Flame Spread, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type HCX - Extreme Temperature - Zero Halogen Jacket, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type MTC - Machine Tool Conduit, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type EFL - Aluminum Core, Light Weight, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type OR - Special Oil Resistant Jacket, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type HC - Hot and Cold Resistant, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type EFST - All Purpose, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type EF - General Construction Grade, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type FGUA - UL Listed, NSF Approved, Food Grade, Liquid Tight, Flexible, Metal Conduit (LFMC)

-

Type FGSS - 316 Stainless Steel, Food Grade, Liquid Tight, Flexible Conduit

-

Type FG - Food Grade, Liquid Tight, Metal Conduit, NSF approved

-

Type HCSS - Hot and Cold Temperature 316 Stainless Steel, Liquid Tight, Flexible, Metal Conduit

-

SHIELDTITE® - EMI/EMP for High-Level Shielding Liquid Tight Flexible Metal Conduit (LFMC)

-

Type NWC - Nuclear Wiring Conduit Liquid Tight Flexible Metal Conduit (LFMC)

-

Type XTHF- Extreme Temperature, Halogen Free, Liquid Tight, Flexible, Metal Conduit

Different Applications for Flexible Metal Conduit

Flexible metal conduit is installed according to national safety codes, protecting wiring from exposure, abuse or intrusion. Conduit is commonly found in places such as the following:

-

Outdoors and underground: Liquid tight conduit is recommended for protecting wiring from moisture, dirt and corrosive materials.

-

Exposed and concealed public areas: Flexible metal conduit is installed to meet safety code, preventing accidental damage to electrical wiring. Conduit protects wiring between junction boxes, elevators, escalators, wheelchair lifts, motors, machine controls and communications, security, surveillance and air conditioning equipment.

-

Manufacturing locations: Flexible metal conduit protects workers and machinery from exposure to electric shock. You can choose among FMC or LFMC types, depending on code requirements and your manufacturing environment. Select among conduit types made to resist high heat, extreme chill, ionizing radiation, radio interference, abrasion, vibration, repetitive motion, soap, detergent, dust, moisture or corrosive atmosphere.

-

Industrial machinery: Flexible metal conduit and liquid tight flexible metal conduit protect cables, wiring or optical fiber to sustain machine productivity. Conduit protects critical control circuits from accident, vibration and crushing force.

-

Data centers and computer networks: Liquid tight flexible metal conduit is tested and approved to protect data cables installed in buildings, outdoors or under ground. Where data needs to be secured, liquid tight flexible metal conduit protects wiring from intrusion and abuse.

Choose Anamet Electrical for Your Flexible Metal Conduit Orders

Anamet Electrical provides time-tested solutions for connecting and protecting wiring in harsh and demanding work environments. If you must meet safety code, our products meet and exceed requirements.

If you have questions about conduit protecting wiring from especially harsh or demanding conditions, contact us today. You can also check our product catalog or request a quote for conduit and fittings meeting your requirements.

/Asset/flexible-metalic.jpg

Industrial Stripwound Metal Hose

Anamet Electrical, Inc. is a leading manufacturer and supplier of industrial stripwound hoses, distributed worldwide. The flexibility, crush resistance and corrosion resistance of this metal hose makes it suitable for industrial use. Our experience and in-house capacity deliver exceptional products that durably protect critical systems.

Here are a few current applications for flexible metal hose:

-

Cord armor

-

Power distribution

-

Mechanical linkage protection

-

Armor for surveillance and entry protection

-

Data networks

We apply decades of experience in manufacturing industrial products for discerning customers worldwide. Our goal is to enable customer safety, success and satisfaction, achieved through focused manufacturing and quality control processes.

Industrial Stripwound Hose Available at Anamet Electrical

Our stripwound hose is ideal for industrial use, made to meet and exceed customers’ needs.

We manufacture two types of industrial stripwound metal hose:

-

Square Lock (SL) Stripwound Hose: The square lock stripwound hose is available in stainless steel, galvanized steel, yellow brass and aluminum. Our type 316 stainless steel hose is time tested to resist corrosion most effectively. Convolution packing, protective metal wire braid and extruded PVC, silicone, polyurethane, and thermoplastic elastic jackets provide protection that surpasses the limitations of bare metal hose.

-

Full Interlock (UI) Stripwound Hose: Our full interlock (UI) stripwound hose, is available in galvanized steel, aluminum, stainless steel, bronze and yellow brass. The interlocked features of this hose enable impressive resistance to crushing force and twisting. Stainless steel hoses also offer corrosion and high-temperature resistance. Metal braid may be applied to this hose, but packing cannot fit in the convolutions of this hose. A variety of extruded polymer jackets are also available to seal this hose from moisture or dust intrusion. This hose was originally called capillary armor, manufactured to protect capillary tubes in mercury-based thermostat and steam control systems.

Industries that use our stripwound metal hose

Here are some of the industries that use our stripwound metal hose:

-

Aerospace

-

Automotive

-

Chemical Processing

-

Construction

-

Food Processing

-

Pharmaceuticals

-

Power Generation

-

Robotics and Automation

-

Mining

-

Mass Transit

-

Machine Controls

Various Applications for the Stainless Steel Stripwound Hose

Stripwound metal hose flexibly protects its contents.

Other applications & benefits of our stripwound metal hose in industrial settings:

-

Harsh environments: Our stainless steel stripwound metal hose is designed to withstand environments that can cause corrosion. Furthermore, it can resist high temperatures to +232°C or 450°F max.

-

Durable safety: The consistently circular cross section of the stripwound metal hose resisting crushing force, and in vacuum or low-pressure environments, it maintains its shape, preventing collapse and damage to wiring.

-

Flexible usage: This flexible hose can go around corners and fit in confined spaces more effectively than rigid conduit. This flexible hose bends, extends and compresses as needed. Due to the spiral configuration of the hose, threaded fittings can be wound onto the hose. Cord grips can also be installed on the hose to provide a reliable connection. You do not need a special flange or collar to install it.

-

Non-ferrous options: Non-ferrous metal stripwound hose such as yellow brass, bronze and aluminum hose avoid striking sparks. Bronze hose provides EMP and EMI shielding, depending on the configuration.

Choose Our Stainless Steel Stripwound Hose to Protect Your Critical Connections.

If you need help determining the right product to meet your needs, contact us or request a quote today. We can help you flexibly connect and protect your critical systems.

/Asset/insdustrial-stripwound.jpg

Fixture Whips

Construction- Constructed of continuously interlocked, zinc-coated steel strip.

- 14 gauge solid or stranded copper white, black, and green wires

- Flexible with high crush resistance.

- 3/8' screw-in, snap-tite connectors on each end.

- Smooth exterior and interior allow for easy pulling and wire fishing.

UL LISTED

RoHS WEEE COMPLIANT /Asset/fixture whip.jpg

Cord Grips

Securing your electrical components is imperative to prevent cable failure and damage in industrial settings where the environments are incredibly harsh and unforgiving. To ensure optimal performance, you should use protection components designed to protect the cables from abrasive elements.

At ANAMET Electrical, Inc., we offer quality cord grips that ensure tight connections and security. We strive to provide durable protective components and conduit to connect and protect our customers' products and projects.

Understanding Cord Grips

Cord grips are commonly found in industrial and commercial settings where electric cables and wires must be connected securely. These components offer extra protection from water, dust, and other environmental elements, ideal for dry and wet applications.

Another benefit of using these components is preventing cable damage and failure caused by over-tightening or loose connections. Furthermore, they're also designed to protect the cable itself from abrasion and wear due to repeated pulling and bending.

Other benefits of using cord grips:

- Protect cables from stress and damage as they run through equipment panels

- Prevent cables from being pulled out of a system

- Relieve stress and strain on the connection and equipment circuitry

- It provides earth grounding when used with an armored cable

- Offers an appropriate level of resistance for tension or holding force

- Provides a reliable termination for bare metal conduit or hose

Due to these features, these cable components have been used in many industries.

ANAMET Electrical, Inc. Cord Grips

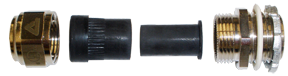

Our technological abilities enabled us to design and produce high-quality cord grips that are second to none. They're made with a versatile gripping solution. Two nesting sleeves allow a fitting to provide a range of grip diameters.

Each cord grip comes with two clamping seals. The outer seal fits over the inner seal, providing a firm grip.

A sealing ring and galvanized steel locknut are provided on each cord grip for reliable termination.

The products we offer:

Stainless Steel Cord Grips

Our AISI-316 stainless steel cord grips have excellent chemical and corrosion resistance since they are higher quality stainless steel. They're durable and ideal for high-performance applications, making them ideal for wet or hostile environments.

Item #s:

Nickel Plated Brass Cord Grips

These components also have two clamping seals and offer excellent corrosion resistance. Since these components are made with brass, they offer high-temperature ductility, high conductivity, and low magnetic permeability.

Item #s:

Our products deliver a comprehensive sealing and clamping range so that you can find your project's ideal size and type. Furthermore, all our products have undergone stringent quality tests and a strict manufacturing process to ensure consistency, so rest assured that every product meets your expectations.

Choose Anamet Electrical, Inc. for Quality Cord Grips

We're committed to providing our customers with superior-quality products and excellent customer service. Our team of highly experienced professionals understands the challenges of industrial projects, so we find a solution that will solve these complexities immediately.

If you have any questions about our products, don't hesitate to contact us today. You may also request a quote for larger projects, and we'll send a competitive price that won't break the bank.

/Asset/cord grip.jpg

CENNOS NEW PRODUCT LINE

(21)Construction

- Constructed of continuously interlocked hot dipped zinc galvanized steel core for exceptional crush and corrosion resistance.

- Durable, sunlight resistant thermoplastic PVC jacket that resists heat, oil and chemical breakdown.

Description

- Flexible metal core liquid tight conduit

- Also available in black by special order

- Uses standard liquid tight connectors for easy installation

- Additional Put-ups available

Specifications

- Galvanized steel core with liquid tight PVC jacket

- Color: Gray and Black

- Temperature range: -4°F to +176°F (-20°C to +80°C)

- UV (sunlight) resistant

- Corrosion resistant

Applications

- Applications requiring liquid tight, 1/4” ID

- Applications where no approvals are required

Certification

RoHS WEEE COMPLIANT

Recommended ANACONDA SEALTITE® Fittings

- Compact 316 Stainless Steel for the best corrosion resistance

- Compact Nickel-Plated Brass for next level corrosion resistance

- Compact Galvanized Steel for corrosion resistance